High-Temperature Furnace Models

Furnaces for High-Quality Industrial/Production Use. Please inquire about the MHI Neverdown™ feature.

All sizes, from large industrial sizes to small. Furnace 1700°C/1760°C/1800°C with MP class heating elements or 1400°C Models with GAXP class heating elements. MHI offers high-uniformity high-temperature furnaces. Specialty furnaces include high power density and large span models, features that the novel heaters and MHI insulation ceramics allow in the construction.

Comparing furnaces? What guarantees do you have for a long-life furnace? Here are a few…

- Is the warranty on Electronics at least 2 Years?

- Is the warranty on Heating Elements at least 1 Year

- Is your furnace made with all stainless steel for a long life? Inside and outside?

- Safety refractory without fibers is used as appropriate, including for the doors.

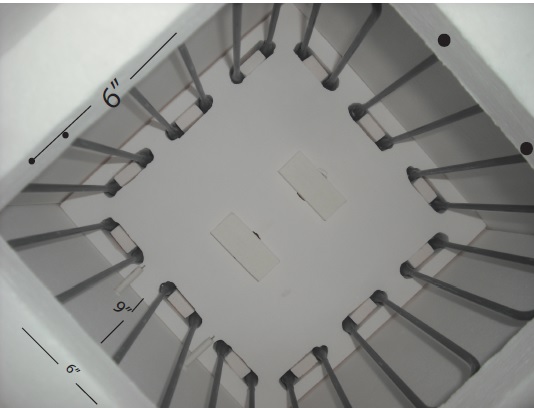

- Top-mounted MHI Moly-silicide heating elements. Best Life.

- High-quality roof hangers?

- Is the exterior wall cooled for safety?

- Lab Scale Furnaces

- Industrial Scale Furnaces

- Steam Ovens

- Control Panels

- Box Furnaces

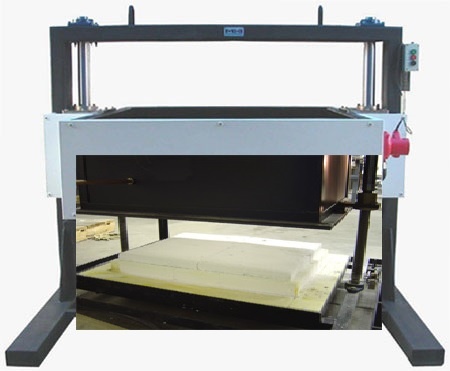

Bottom Loading

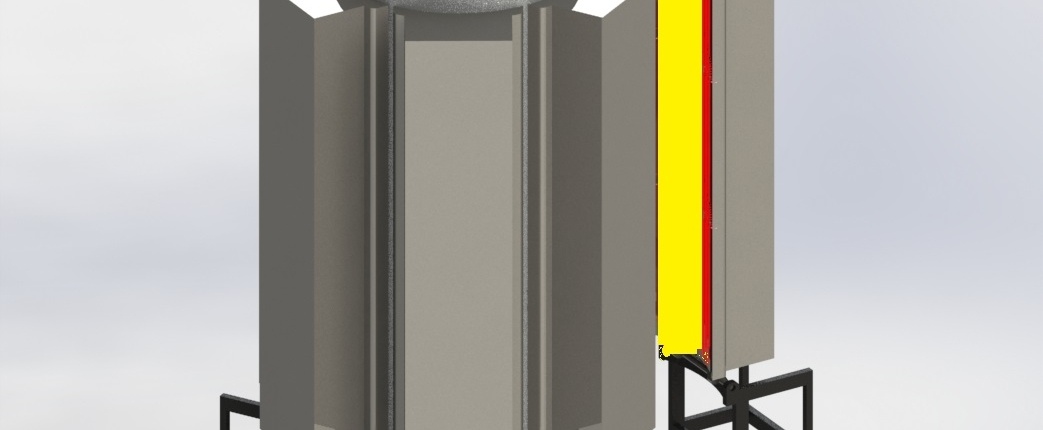

Vertical Furnaces

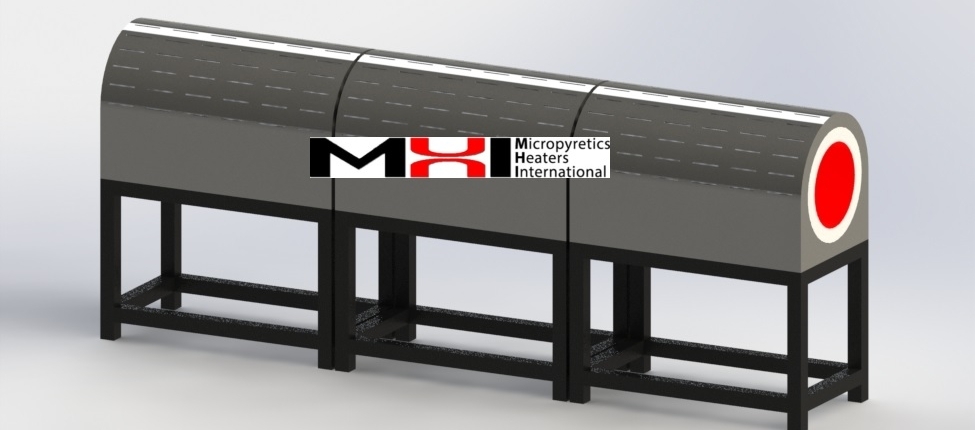

Horizontal Tube Furnace

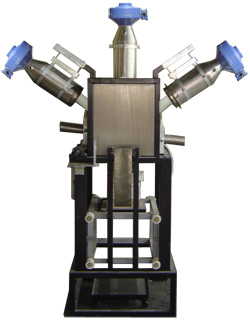

Tensile Testing

Compact Slider

Stackable Modules - For easy purchase of spare parts, visit our store – (spare parts)Fiber Free Refractory

MicroFurnacesNew Micro-Furnace Models

Productivity vs Temperature (PDF)

|

Furnace FeaturesSafety, Warranty, Non-sag High Temperature Roofs, Unique FiberFree™ Hearths, Great Uniformity Designed with modern materials Add clean environmental gases-high temperature steam/air-plasma Large Furnaces

|

|||||||||||||||

FurnacesComplete Digital Controls/Data Acquisition Please click on the furnace type below.

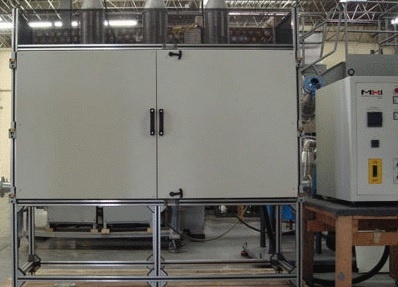

MHI is an energy-efficient high-temperature furnace and general furnace manufacturer. Our furnaces meet the highest standards for quality, energy efficiency, and performance. Several Sizes are available: From the laboratory, prototyping intermediate-scale, to large-scale with established high-safety heating devices, elements, furnaces, and refractories. Single-phase to three-phase models 4 kW – 4MW.

|

|||||||||||||||||||

High Productivity ModelsOffers convection and best running value proposition One year warranty includes the heating elements. |

| Model

Internal Dimensions in inches |

Size |

| THF-1400-6-GAXP

(6 Cu Ft) 1400C Hybrid -THF-1400-6-GAXP Motorized Top Lift |

16″H x 24″W x 24″D |

| THF-1760-6-MP (6 Cu Ft)

1700C |

16″H x 24″W x 24″D |

| THF-1400-12-GAXP (12 Cu Ft) 1400C

Hybrid -THF-1400-12-GAXP Motorized Top Lift |

24″H x 46″W x 46″D |

Dross reduction Attachments to Furnaces e.g. Aluminum

- Reduced Energy Costs – Energy efficiencies of 0.2 kWhr/lb for melting with no emissions.

- Improved melting from ultra-clean metal.

- Clean melting, with dross values less than 0.5% depending on the configuration.

- No requirement for nitrogen, argon, or chemical fluxes – significantly reducing operating costs and the environmental impact.

- Extremely small equipment footprint as shown above in Figure 1.

- Quiet operation – Zero noise -much lower than typical, conventional plasma systems.

- High energy density nearly four times compared to the standard And.

Steam Ovens

Add Steam to an MHI Furnace or Oven MHI makes it easy for the steam inlet port. New furnace prices have been dramatically reduced so that a steam inlet port and steam generator may be ordered with the furnace.

- MHI High-Intensity Offerings

- So many choices based on our years of understanding your specific needs

- Furnace Safety

- Data Acquisition for MHI Furnaces – MHI-DACS

- Unique easy connect features. Easy disconnect for tube furnaces.

- Easy connect terminals for better energy management and cooler terminals

- Unmatched high alumina roof hanger designs. Do not settle for a furnace without roof hangers.

- Multi-tap transformers.

- Uniformity: High order of +/- 2°C temperature uniformity

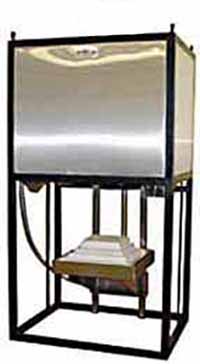

- MHI innovates with powerful concentrator technology. Our power concentrator furnace shown below has the highest energy density in its size class. PC furnaces have a very high power concentration (J/s/m3) to enable a concentrated power processing of materials.

- Your Choice. Concentrate Hot Air, Concentrate Hot-Steam or Hot Electrons or Hot-Ions

- Call MHI at 513-772-0404 for more information. The fastest way for heat delivery is now with enhanced convection + radiation + e-Ion heavy assist.

- High Intensity for Aluminum Furnaces to Save Energy and Dross.

Maximum Processing Temperature Size Power For 3DSintering™ Power Concentrator Furnace Size Contact Online For liquid aluminum holding Variable Contact Online 1600-1700°C 4 x 9 x 9 15kW 1200°C 8 x 8 x 8

8 x 8 x 8

8 x 8 x 812kW

23kW

35kW1000°C 4 x 8 x 8

4 x 8 x 8

4 x 8 x 810kW

20kW

30kW

| Model Number | Temperature | Interior Dimensions |

| LTF2 | 1100°C – 1700°C (2012°F – 3092°F) |

16″H x 24″W x 24″D |

| LTF 2-1400 | 1400°C (2552°F Max) |

16″H x 24″W x 24″D |

| THF-1400-(6-12)- GAXP | 1400°C (2552°F Max) |

6-12 Cubic Foot Furnace |

| M18-40 | Up to 1760°C (1800°C/3272°F Max) |

12″H x 12″W x 16″D |

| H14 | 1400°C (2552°F Max) |

8″H x 7″W x 8″D |

| M14 | 1400°C (2552°F Max) |

12″H x 12″W x 16″D |

| Request Quote | ||

More Box Furnace Models…

Specialty Furnaces

Double-wall stainless multiple high-quality insulation layers enable uniformity.

|

Uniformity comes from the thermal arrangement of heating elements. MHI furnaces offer:

|

MHI Specialty Furnace Features

Safety, Warranty, Non-sag High-Temperature Roofs, Unique FiberFree™ Hearths, Great Uniformity

Designed with modern materials and state-of-the-art technology platforms

Add clean environmental gases like high-temperature steam or air-plasma

MHI Furnace Features

Safety, Warranty, Non-sag High-Temperature Roofs, Unique FiberFree™ Hearths, Great Uniformity

Designed with modern materials and state-of-the-art technology platforms

Add clean environmental gases like high-temperature steam or air-plasma

Large Long Furnaces

Collage of more features

|

|

|

|

|

| Furnace Specials | Multi-Tap Transformers | MHI Quality Mark | TRIPAN Control Panels | Sub-Assembly catalogs |

MHI manufactures novel devices when standard furnaces cannot meet your needs. Please contact us.