Introducing our Latest Innovation with Steam-Air Controlled Ovens. Contact MHI.

Now Offering 1 Year Warranty on Heating Elements for Certain Classes of MHI Furnaces. Please contact MHI for full details.

For easy purchase of spare parts visit our store – (spare parts)

|

|

| Request Quote |

All Ovens batch and continuous available in steam-air atmospheres.

Article: How Delta-Star switching can be used for energy savings

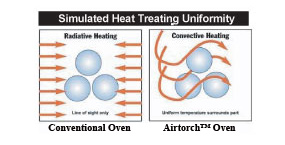

| Very often the secret to high productivity and reliable parts lies in the uniformity of the furnace/oven. For production ovens, uniformity is a key concern for ensuring quality. Energy efficiency and uniformity are increased by improving the delta-star transition where possible, and also by introducing the proper convection environment. The unique Airtorch models and steam generators offered by MHI are able to offer the correct convection in ovens and furnaces. |

|

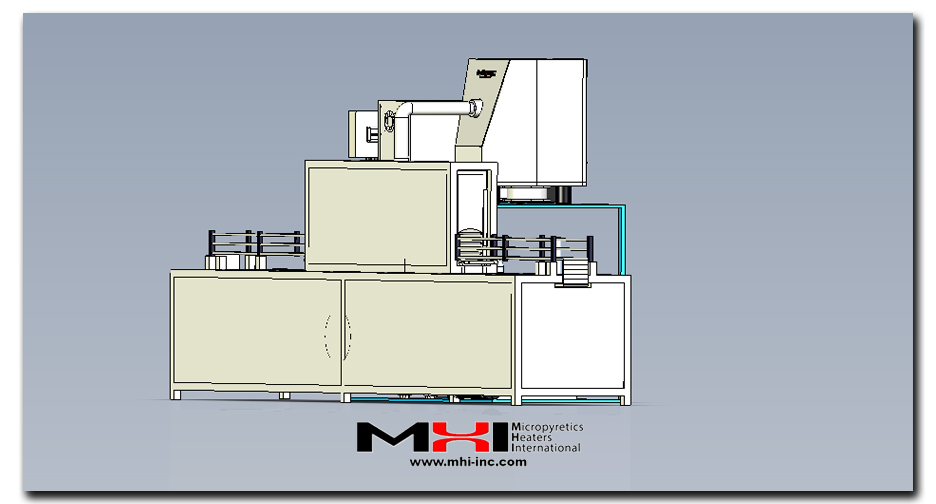

Does convection enhance uniformity?(read article) MHI offers heated process gas and also superheated steam generators The designs below are examples of Efficient Power and Uniform Temperature for an Oven with Airtorch or Steam. Process Gas or Superheated Steam Input |

| Specifications |

DISCHARGE TYPE OVENS Example |

DISCHARGE TYPE OVENS Example |

|

| Air or Steam Generator Sources |

OVEN (1kW) for Air or Steam or Moxtures (with VTA for Air, HGA for steam) |

||

| Description: |

Energy efficient circulating Hot Air or Steam Oven with convertible compartments and uniform temperature distribution.

|

Energy efficient circulating Hot Air or Steam Oven with convertible compartments and uniform temperature distribution.

|

|

| Internal Dimensions: |

• 24” (D) x 24” (W) x 14” (H)

• 8,064 Cubic Inches • 132,145 Cubic Centimeters |

• 24” (D) x 24” (W) x 28” (H)

• 16,128 Cubic Inches • 264,290 Cubic Centimeters |

For Continuous TypeClick Here |

| External Dimensions: |

43.25” x 34.5” x 69” (H) approximate

|

43.25” x 34.5” x 83.0” (H)

|

|

| Internal Compartments: |

• Two compartments of each of size:

24” x 24” x 7” (H). • The two compartments can be converted into a single compartment of large size: 24” x 24” x 14” (H), by removing the tray. |

• Three compartments of each of size:

24” (D) x 24” (W) x 9” (H). • The three compartments can be converted into a single (24” x 24” x 28”) or two compartments, by removing the trays. |

|

| Temperature: |

up to 250°C

|

up to 250°C

|

|

| Power: | |||

| Power Supply: |

240 VAC, 1 phase, 60Hz

|

240 VAC, 1 phase, 60 Hz

|

|

| Transformers: |

Not required for standard voltages

|

1 Transformer

|

|

| Controls: |

BPAN-O-2010 plus

|

BPAN-O-2010 plus or other MHI

|

|

| Typical Applications: |

Ageing, drying, curing, dental, laboratory and many more.

|

Ageing, drying, curing, dental, laboratory and many more.

|

|

| Request Quote | |||

Example of use for continuous ovens

|

On account of the Airtorch Versatility Special Convective Ovens can be considered for moving parts for debinding, degreasing. Use steam for paint removal.

|

What’s New :: Read Testimonials :: Conversion Calculator

MHI also manufactures: Custom Continuous Convective Ovens and Hydrogen Annealing Furnaces