Steam Media Gallery

Steam Media Gallery

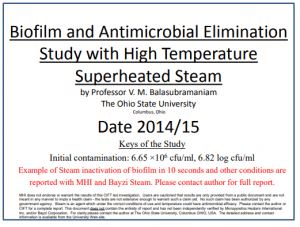

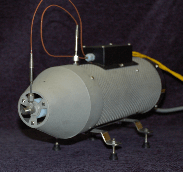

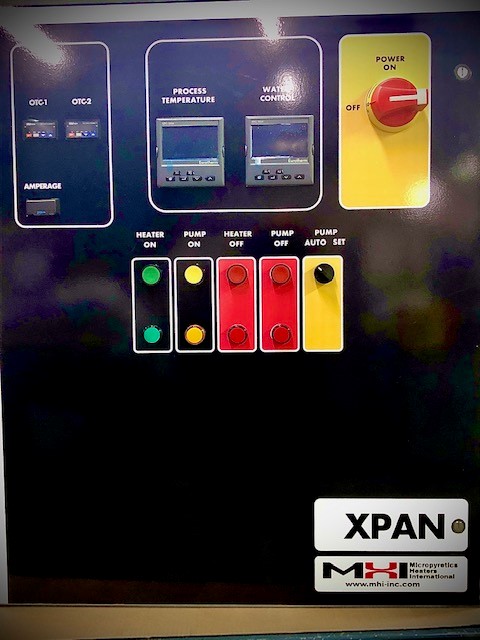

Disinfection Studies, Videos, Biomass, Antimicrobial possibilities, Oxidation, Fiber Conditioning, Textiles Cutting Nozzles and more…..no mess, low power, full quality steam and high speed use for from cutting to shrinkwrap. Contact us for more information. OAB® Models and MightSteam Models Information Request

General Safety Considerations with Handheld Airtorch and Steam Devices.