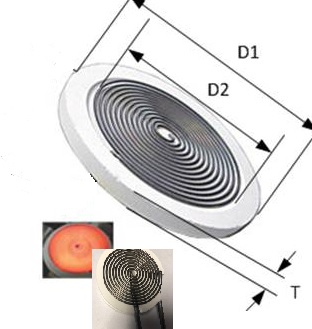

Spiral Shaped Microheaters

The objective of the use of free radiating devices is to maximize the radiative POWER transfer from the heating elements.

1400°C Models (GAXP® Material) | |

MC-GAXP®-30 (Otrthogonal terminals)

| MC-GAXP®-130 (Orthogonal terminals) |

MC-GAXP®-375 (Orthogonal terminals)

| MC-GAXP®-485 (Orthogonal terminals)

|

| Control Panels | |

![]() (Ceramic base provided with microheater doesnot have a lip. Picture only for illustrative purposes only.)

(Ceramic base provided with microheater doesnot have a lip. Picture only for illustrative purposes only.)

Note that the maximum temperature is at the center of the spiral region unless asymmetric power delivery is required

In the diagram above D1 and D2 are separated by 0.1″ T is 0.25″ and H is 2.5″

For obtaining maximum temperature MHI controls are highly recommended. Large diameter GAXP® microheaters could develop some springiness from induced magnetic forces. Potting in ceramic paste is allowed as long as care is taken to factor-in the loss of any thermocouple response in the measured temperature. Note element temperature will be higher and maximum element temperature should not be exceeded. In the free radiation mode the power can be maximized.

The objective of the use for free radiating devices is to maximize the radiative POWER transfer from the heating elements. If the heating element is covered with insulation, the objective of the user changes to obtain a certain temperature inside the insulated region. ![]() The control of temperature inside a chamber or power maximization in a free radiating mode can be made with MHI temperature and/or power controllers. When covered the power and current will be lower and the element temperature can be exceeded quickly if not monitored and controlled. For either objective, one cannot exceed the rated temperature or maximum current of the heating element. Power output will be lower in enclosed radiation mode with a temperature control feature as opposed to or in addition to the power control.

The control of temperature inside a chamber or power maximization in a free radiating mode can be made with MHI temperature and/or power controllers. When covered the power and current will be lower and the element temperature can be exceeded quickly if not monitored and controlled. For either objective, one cannot exceed the rated temperature or maximum current of the heating element. Power output will be lower in enclosed radiation mode with a temperature control feature as opposed to or in addition to the power control.

1900°C MC Models Shown Below | |

MC-MP-170 or MC-MP-170-IPL (Crossline terminals or In-plane terminals) | |

| Control Panel Features | |